Overview:

Inventory is required at different locations within a business in order to function smoothly and without hindrance. For this reason, inventory Locations are used to consolidate and manage all goods and material that a business holds for the purpose of resale or repair. Inventory Locations allow you to specify availability and status of a product. An inventory location can be a truck for field services, a warehouse, or anywhere material may be stored.

This document is intended as an explanation of the Location Search feature in SmartWare and assumes you possess a general knowledge of inventory and inventory locations.

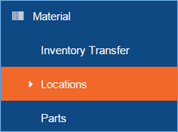

Navigate to Locations

You can access the locations panel from the following locations:

- From the main menu on the left side of the screen, select Material and then Locations

SmartWare – Main Menu

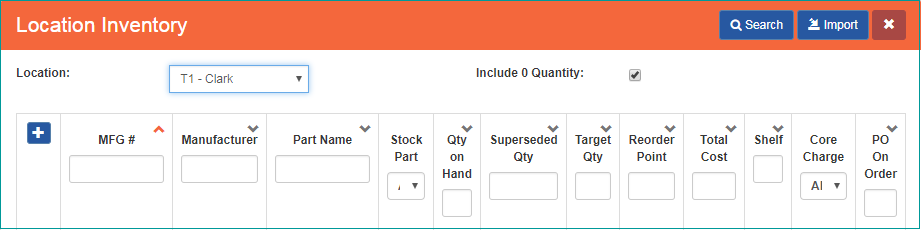

Search for Location

The Location panel will allow you to define the search criteria you would like to use to search for locations

Location – Search

In the Locations panel, enter a single item or combination of items

Below is a brief explanation of each available location search criteria:

| Search Criteria | Functionality |

|---|---|

| Location | (required) Determines the location you would like to view inventory for |

| Include 0 Quantity |

Determines if 0 quantity parts are displayed

|

Once you have finished entering all search criteria, click the  button

button

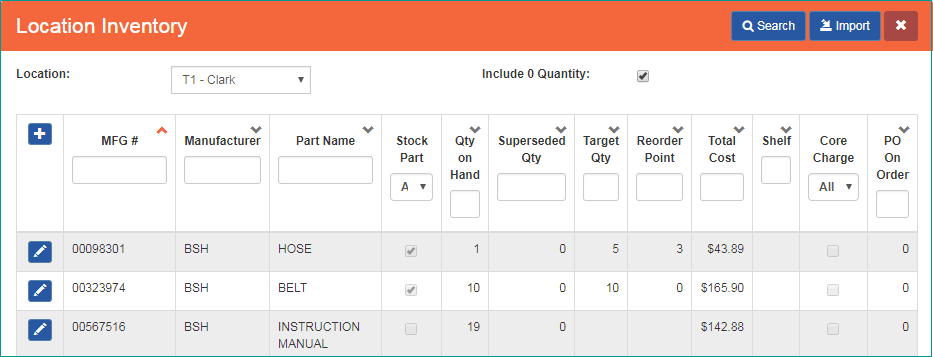

A list of parts currently associated with the selected location will be displayed in the grid below the Location search fields

Location – results grid

Location Grid - Defined

Below is a brief explanation of each column available from the location results grid:

| Search Criteria | Functionality |

|---|---|

|

(New Record) Allows you to add a part that exist under Material | Parts to the selected location |

|

(Edit Inventory Quantities) Opens the Location Inventory panel for the selected part allowing you to view location part information and make changes if needed |

| MFG # | Manufacture part number that was entered on the part record |

| Manufacturer | Part name that was entered on the part record |

| Stock Part |

Stock Parts are considered any parts that have a reorder point entered on a Location Part

|

| Qty on Hand |

Inventory quantity currently available for the selected part and location

|

| Superseded Qty | Shows the quantity of the superseded parts for this part. Marcone parts that have been superseded and User Added parts will show as blank in this column |

| Target Qty | Target quantity that was entered on the reorder points panel for the selected location and part |

| Reorder Point | Reorder point that was entered on the reorder points panel for the selected location and part |

| Total Cost |

Represents the total cost of all parts on the location

|

| Core Charge | Indicates if the part was marked as having a core charge applied to it in Material | Parts

|

|

Export to Excel button will export a list of all rows/columns current displayed on the grid

|

| PO On Order | Shows what quantity of the part is on a purchase order for the location (based on Expected Receive Location instead of Ship To) |

Checked (default value): Parts with quantity 0 will be included in the inventory list returned for the selected location

Checked (default value): Parts with quantity 0 will be included in the inventory list returned for the selected location Unchecked: Parts with quantity of 0 will not be included in the inventory list returned for the selected location

Unchecked: Parts with quantity of 0 will not be included in the inventory list returned for the selected location Checked: Location Part has reorder points entered and is considered a stock part

Checked: Location Part has reorder points entered and is considered a stock part Unchecked: Location Part does not have reorder points entered and is not considered a stock part

Unchecked: Location Part does not have reorder points entered and is not considered a stock part